Water Cooled Water Chiller

Water Cooled Chiller

• High Efficiency

• Stable and Reliable

• Accurate Capacity Adjust

• Intelligent Control

• Eco-Friendly

Water Cooled Water Chiller with Scroll Compressor (Water Cooled Scroll Chiller)

Features

Scroll Compressor

High efficiency scroll type compressor is hermetically sealed, quiet running and supported on rubber mounts to minimise vibration. All compressors are provided with an internal overload protection, and incorporate crankcase heater for smooth start-up under any conditions. Famous brand compressor: Copeland, Panasonic and Danfoss. More reliable.

Condenser

Condenser built with high efficiency shell & tube type heat exchanger, factory insulated with flexible close cell material.

Evaporator

Evaporator built with high efficiency shell & tube type heat exchanger, factory insulated with flexible close cell material.

Multiple protection

The electric panel consists of compressor breaker, compressor contactor, phase sequence relay, control circuit breaker, microprocessor control with function display.

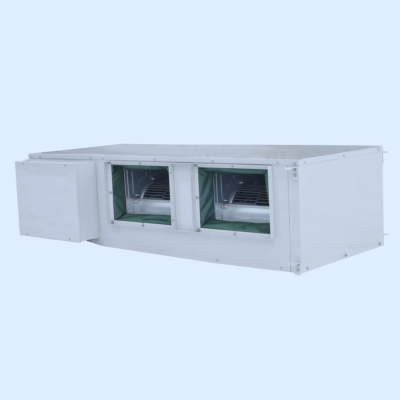

Water Cooled Water Chiller with Screw Compressor (Water Cooled Screw Chiller)

Features

Advanced Twin-rotor Screw Compressor

The product adopts semi-hermetic twin-rotor screw compressor. Compared with open structure, it has the advantages of less refrigerant leakage, high transmission efficiency and no heat dissipation in the equipment room. The screw rotor adopts the profile design undergoing the optimized compression process to ensure the compressor has excellent volumetric efficiency and low leakage. At the same time, the twin-screw rotor adopts five teeth to six teeth asymmetric design, machining accuracy up to micron level and ensuring stable operation. Large capacity motor design, high motor efficiency. Suitable gas passage and clearance design is adopted inside the motor, and the refrigerant is fixed around the motor to ensure full cooling of the motor.

Condenser

Condenser built with high efficiency shell & tube type heat exchanger, factory insulated with flexible close cell material.

Evaporator

Evaporator built with high efficiency shell & tube type heat exchanger, factory insulated with flexible close cell material.

Multiple protection

The electric panel consists of compressor breaker, compressor contactor, phase sequence relay, control circuit breaker, microprocessor control with function display. LCD display, touch screen control panel as standard.

Suggestion for energy conservation:

1. Choose the right pressure head for chilled water pump and cooling water pump.

Choose proper pipe diameter and water velocity.

Minimize pipe joint, reducing joints, pipe reducers, manifolds, and valves unnecessary to reduce local resistance loss.

Choose proper water strainer (structure/meshes) and periodically clean.

2. Using a variable frequency water pump is recommended as it can reduce energy consumption by 30%-45%.

3. Using a water distributor and valves between floors or terminal SV to prevent chilled water from circulating in non-working terminals is recommended.

4. Do periodic cleaning of cooling tower and pipe system.

5. Select a location that provides sufficient air-flow for both air-inlet and outlet.

6. Make appropriate adjustments to chilled water inlet/outlet temperature and temperature difference according to the local climate.